Advances in the development of intelligent, self-healing technology

An engineering team from the University of Nebraska-Lincoln is one step closer to realizing a breakthrough that sounds like science fiction: robots and wearable devices capable of healing themselves after suffering damage, just like human or plant skin.

The project is led by professor Eric Markvicka, in partnership with graduate students Ethan Krings and Patrick McManigal. The trio presented the latest research results during the IEEE International Conference on Robotics and Automation (ICRA 2025), held in Atlanta.

The study proposes a systemic solution for self-repairing soft robotics, with a mechanism that detects damage – such as punctures or intense pressure -, locates the problem and activates a regeneration process completely autonomously.

The impact of the work was recognized: out of 1,606 papers submitted to the conference, the team’s article was one of the 39 finalists for the ICRA 2025 Best Paper award, as well as competing in the Best Student Paper and Best Project in Mechanism and Design categories.

According to Markvicka, the proposal addresses a persistent challenge in the field of biomimetics – an area that seeks to draw inspiration from nature to create technological solutions:

“In our community, there is a big movement to replicate traditional rigid systems using soft materials, and a huge advance in biomimetics,” explained the professor. “Although we’ve already managed to create stretchable electronics and actuators that are soft and conformable, they generally don’t mimic biology in their ability to respond to damage and then initiate automatic repair.”

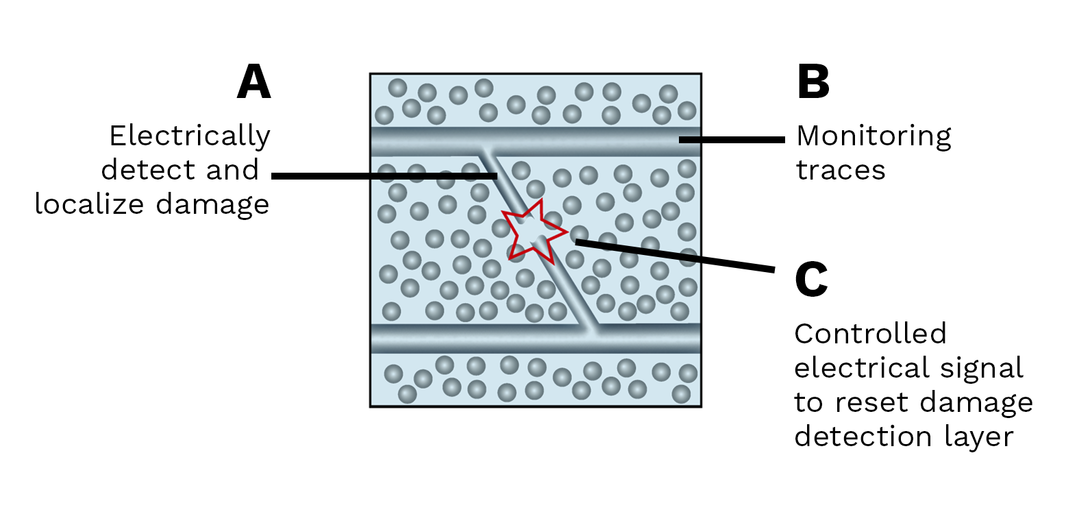

The project’s central innovation is a three-layer actuator – the robot’s so-called “muscle” – which mimics the regenerative functioning of living tissue.

- Bottom layer (damage detection): composed of a soft electronic “skin” made of liquid metal microdroplets embedded in silicone.

- Middle layer (self-healing): a rigid thermoplastic elastomer that can melt and fuse again.

- Upper layer (movement): activated by water pressure, responsible for generating physical movement.

The process begins with the application of five monitoring currents to the lower skin, connected to a microcontroller. When damaged, the layer forms a new electrical network – the “wound signature” – which is identified by the system. The current then increases, transforming this network into a localized Joule heater.

The heat generated reactivates the intermediate layer, sealing the damaged area within a few minutes.

An essential innovation of the project is the ability to restart the system after repair, allowing for multiple cycles of damage and healing. To do this, the researchers turned to electromigration, a phenomenon that is normally undesirable in electronic circuits.

“Electromigration is usually seen as something extremely negative,” said Markvicka. “It’s one of the bottlenecks preventing the miniaturization of electronics. Here, we use it in a unique and very positive way. Instead of trying to avoid it, we are, for the first time, using it to erase trails that we previously considered permanent.”

Advertisement - Continue Reading Below

As the electrical current increases, the system forces the metal atoms to move, erasing the electrical signature of the previous damage and allowing the cycle of detection and healing to repeat itself indefinitely.

The technology has the potential to transform several sectors, especially where systems face frequent risks of mechanical damage.

In agricultural states like Nebraska, for example, robots in the field are constantly exposed to branches, thorns, fragments of plastic or glass. In urban environments, wearable health monitoring devices require durability in the face of daily use.

What’s more, the environmental impact can be significant. Many consumer electronics only last one or two years, generating tons of electronic waste with toxic substances such as lead and mercury.

“If we can create materials that can autonomously detect when damage has occurred, and then initiate self-repair mechanisms, that would be really transformative,” said the professor.

The work received funding from the National Science Foundation (NSF), NASA Nebraska EPSCoR and the Nebraska Tobacco Settlement Biomedical Research Development Fund.

With the international recognition and technical advances achieved, the team is now targeting practical applications and future collaborations with industries focused on robotics, digital health and technological sustainability.