Custom Bone Grafts: The Future of Orthopedics with 3D Printing

What if it were possible to 3D print custom-made bones for each patient? That’s the question driving a group of researchers at the University of Waterloo in Canada, who are developing a biocompatible material that can be 3D printed with high precision — a solution that could revolutionize reconstructive surgery.

The project is led by Dr. Thomas Willett from the Department of Systems Design Engineering, whose direct collaboration with orthopedic surgeons at Mount Sinai Hospital in Toronto sparked the idea.

“I realized that the methods being used, while effective, were extremely complex and required a high level of skill,” said Willett. “I thought we could do something with engineering—using 3D printing to produce a bone graft.”

A Personalized Solution to an Age-Old Challenge

Today, replacing damaged bones typically relies on metal implants or donated bone tissue grafts—both of which are difficult to precisely match to a patient’s unique anatomy. This makes the procedure more complex and increases the risk of rejection or complications.

With a material designed for 3D printing, surgeons could create grafts with shapes and structures tailored to each individual case. This would not only simplify the procedure but also enhance the safety and effectiveness of the surgery.

“3D printing would also allow us to add engineered features that help keep the graft in place,” Willett said. “That would eliminate the need for the metal screws and plates surgeons usually rely on.”

“We could have a fully customizable material for the patient, which would have a major impact on the success of bone grafts and surgical outcomes.”

Advertisement - Continue Reading Below

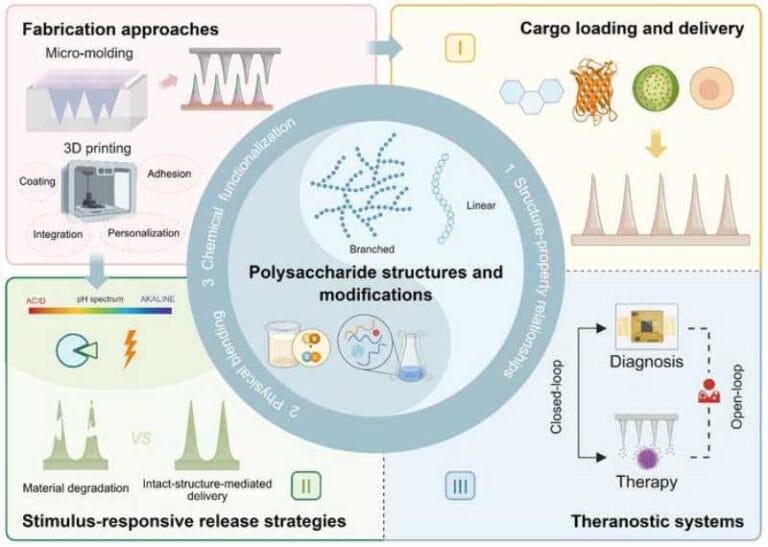

The Science Behind the New Graft

With support from the Canadian Institutes of Health Research, Willett and Dr. Maud Gorbet, director of the university’s Biomedical Engineering program, assembled a multidisciplinary team to turn this idea into reality. Among the collaborators are Dr. Dibakar Mondal, Dr. Sanaz Saadatmand Hashemi, and PhD candidate Elizabeth Diederichs, who is still involved in the project.

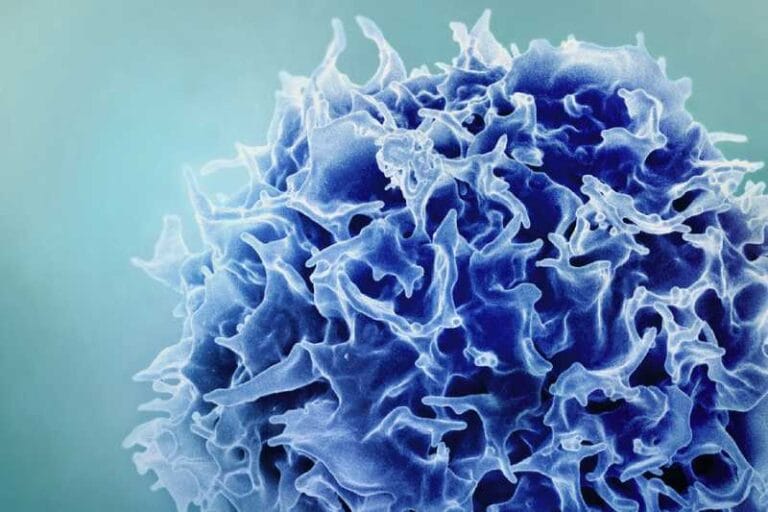

The focus of the research is on the development of a nanocomposite material, created by combining a triglyceride (a substance similar to fat) with hydroxyapatite nanoparticles — a component naturally present in bones.

“The hydroxyapatite particles play several roles,” explained Willett. “They provide mechanical reinforcement, making the material stiffer and stronger. They also create a surface that is conducive to the material bonding with bone cells.”

Advertisement - Continue Reading Below

As the body regenerates, the graft interacts with the natural tissues and is slowly replaced by new bone, promoting a more efficient and natural recovery. A study published in 2024 in the Journal of Biomedical Materials Research reinforced the feasibility of using nanoscale hydroxyapatite for this type of application.

Balance between strength and integration

The current stage of the project is material optimization. The goal is to find a balance between structural strength and the ability to be gradually absorbed by the body. Researcher Elizabeth Diederichs highlights the challenges of this phase:

“The challenge now is optimization,” Diederichs explained. “It’s a balancing act between all the qualities we need.”

Advertisement - Continue Reading Below

The material must be durable enough to withstand the loads of the human body but also capable of degrading at the ideal rate to allow natural bone growth to take its place.

“We can perform CT scans and use computer-aided design to develop a model of the bone piece that needs to be printed,” said Willett. “We could use this process for any bone that has lost a significant part or has a complex geometry.”

Applications beyond human medicine

In addition to offering significant benefits in human orthopedic surgeries, 3D-printed grafts also have the potential for use in veterinary medicine. This could prevent amputations in pets, improving their quality of life.

The work of the Waterloo team has the potential to radically change the way bone grafts are produced and applied, bringing medicine closer to a more precise, safe, and personalized future.

“I find this very exciting,” said Diederichs. “We could have a fully customizable material for the patient, which would have a huge impact on the success of bone grafts and surgical outcomes.”

Source: University of Waterloo