NASA plans to build a rail system on the Moon

As NASA sets its sights on establishing a permanent human presence on the Moon in the coming decades, the space agency is exploring innovative ways to transport materials and cargo across the lunar surface. One concept that has recently gained traction is the idea of building a levitating “rail system” on the Moon, dubbed the Flexible Levitation on a Track (FLOAT) project.

The FLOAT system is envisioned as a network of tracks made from a three-layer film that would unroll directly onto the lunar surface. The bottom layer would be composed of graphite, enabling magnetic robots to levitate above the track using a phenomenon called diamagnetic levitation. The middle layer would consist of a flex-circuit capable of generating an electromagnetic thrust, propelling the robots along the tracks. An optional third layer could incorporate thin-film solar panels to generate power for the lunar base.

According to Ethan Schaler, a robotic engineer at NASA’s Jet Propulsion Laboratory and the leader of the FLOAT project, the primary goal is to “build the first lunar rail system that provides reliable, autonomous, and efficient cargo transportation.” Schaler emphasizes the importance of a durable and long-lived robotic transportation system for the daily operations of a sustainable lunar base, which NASA hopes to establish in the 2030s as part of the Artemis mission.

The initial design calls for unpowered magnetic robots that would levitate on the three-layer track, reducing abrasion caused by lunar dust – a significant challenge for traditional wheeled or tracked vehicles on the Moon. These robots could carry rail cars moving at a speed of about 1.6 km/h (1 mph) and could transport up to 100 tons of material per day to and from the future lunar base.

One of the key advantages of the FLOAT system is its flexibility and ease of deployment. Unlike conventional roads, railways, or cableways, the FLOAT tracks can be unrolled directly onto the lunar regolith (soil), minimizing the need for major on-site construction. This feature would allow the network of tracks to be reconfigured and expanded over time to match the evolving needs of the lunar base.

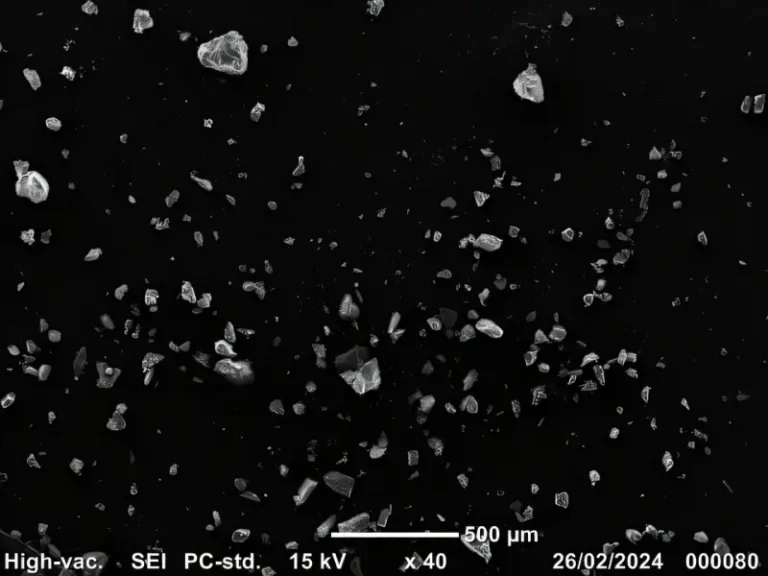

The FLOAT project has recently been approved for additional funding and has moved into the second phase of NASA’s Innovative Advanced Concepts (NIAC) program, which aims to develop futuristic ideas for space exploration. In this phase, the team will focus on retiring risks related to the manufacture, deployment, control, and long-term operation of the system by designing, manufacturing, and testing a series of sub-scale robot and track prototypes.

The team will also investigate the impacts of environmental factors, such as temperature, radiation, and lunar regolith contamination, on the system’s performance and longevity. Additionally, they will work on defining a technology roadmap to address gaps and mature the manufacturing capabilities for critical hardware components, such as large-area magnetic arrays and flex-circuit boards.

The FLOAT system is not the only “science fiction” project in the NIAC program that has advanced to the next phase of development. Other concepts include fluid-based telescopes and plasma-powered rockets, reflecting NASA’s commitment to exploring cutting-edge technologies for future space exploration missions.

While the idea of a levitating rail system on the Moon may sound like something straight out of a science fiction novel, NASA’s FLOAT project demonstrates the agency’s willingness to embrace unconventional and innovative solutions to address the challenges of establishing a sustainable human presence on the lunar surface.

As NASA prepares for its ambitious Artemis mission, which aims to send astronauts back to the Moon as early as 2026, the development of robust and efficient transportation systems will be crucial for the success of future lunar operations. The FLOAT system could potentially revolutionize the way materials and cargo are transported on the Moon, paving the way for a new era of lunar exploration and scientific discovery.